Atta Plant

Product Details:

- Product Type Atta Plant

- General Use Wheat Flour Milling

- Weight (kg) 4200 Kilograms (kg)

- Computerized No

- Automatic Yes

- Control System PLC Control

- Milling System Roller Mill

- Click to View more

X

Atta Plant Price And Quantity

- 1 Set

- INR

Atta Plant Product Specifications

- 380 V Volt (v)

- Atta Plant

- Yes

- Wheat Flour Milling

- No

- PLC Control

- Wheat

- Roller Mill

- Low noise operation, High efficiency, Robust construction

- 6500x2000x3600 mm Millimeter (mm)

- 4200 Kilograms (kg)

- Blue

Atta Plant Trade Information

- 10 Set Per Month

- 7 Days

Product Description

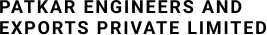

With vast industry experience we are passionately involved in manufacturing and supplying a broad array of Atta plant. Under the strict guidance to our professionals, this machine is manufactured with the help of latest technology by utilizing high quality raw materials in line with set industry norms. Attached with a cleaning system, offered machine is used for grinding ad sieving food grains. Moreover, this Atta Plant can e availed from us in different specifications and sizes at reasonable rates.

Features:

- Robust construction

- Easy operation

- Corrosion resistance

- Superior performance

Advanced Automation for Seamless Milling

The Atta Plant incorporates a PLC-controlled roller mill, providing sophisticated automation for wheat flour milling. This ensures accuracy and minimizes human intervention, enhancing operational safety and output consistency. Operators can monitor system performance in real time, streamlining workflow and reducing labor costs.

Reliable After-Sales Support

Beyond initial installation, comprehensive after-sales service and spare parts availability are included. Manufacturers can rely on swift technical support, routine maintenance, and immediate access to original spares, extending machine life and ensuring uninterrupted flour production.

Built for Industrial Environments

With a robust construction weighing 4200 kg and a powder-coated finish, this Atta Plant withstands industrial wear and tear. Its large capacity hopper and efficient roller milling system are designed for continuous, heavy-duty use, maximizing productivity and minimizing downtime.

FAQs of Atta Plant:

Q: How does the installation process for the Atta Plant work?

A: Once your order is confirmed, our team provides full on-site installation by trained professionals. The service includes setting up the plant, configuring the PLC control system, and running operational tests to ensure optimal functionality before handover.Q: What kind of wheat flour milling applications is this plant suitable for?

A: This Atta Plant is designed for industrial use, making it ideal for large-scale wheat flour production in manufacturing facilities, mills, and processing units that require continuous, high-capacity output.Q: When can I expect after-sales service or spare parts if needed?

A: Our after-sales service and spare parts support are available promptly after installation. You can contact our service team any time for technical assistance, routine maintenance, or spare part requirements.Q: Where can the Atta Plant be installed?

A: The plant is suitable for installation in industrial environments across India. It requires a suitable space (6500x2000x3600 mm), proper ventilation, and access to a stable three-phase 380V power supply.Q: What process does the Atta Plant use to mill wheat into flour?

A: The plant utilizes a roller milling system controlled by an automated PLC unit. Wheat is fed into the 250 kg hopper, then processed through rollers to produce fine, high-quality flour efficiently.Q: How is the Atta Plant maintained for optimal performance?

A: Routine maintenance involves scheduled inspections, cleaning, and replacing worn-out parts. Our after-sales service ensures you receive timely support and original spare parts for maximizing machine lifespan and minimizing downtime.Q: What are the primary benefits of using this automatic Atta Plant?

A: Key benefits include high milling efficiency, low noise operation, robust construction, reliable automation, and dedicated after-sales support. These features collectively deliver consistent flour quality and trouble-free operation for industrial-scale producers.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free